Una segunda vida para el agua

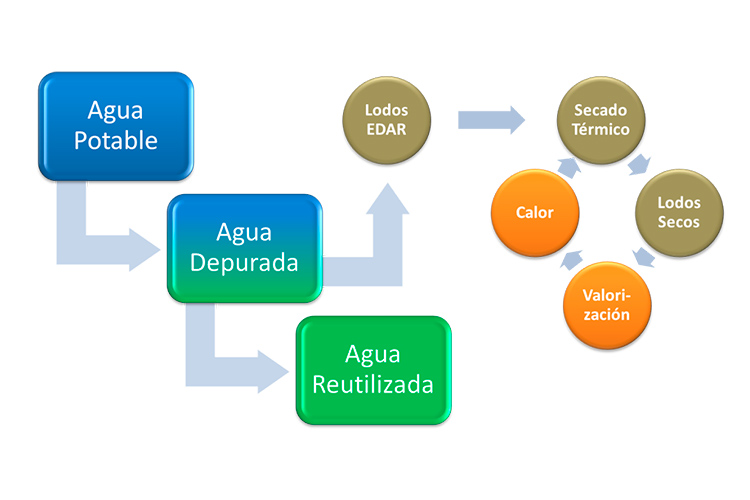

La depuración de las aguas residuales se basa en eliminar todos los residuos que ha ido acumulando el agua residual y devolverla al medio con las condiciones óptimas, para proteger los ecosistemas acuáticos, evitar riesgos para la salud pública y obtener agua apta para su reutilización. Así se asegura el futuro de próximas generaciones y del medioambiente, logrando un desarrollo sostenible. Aguas de Alicante realiza la gestión completa del ciclo integral del agua en el municipio de Alicante. Con el fin de completar el ciclo del agua y devolverla al medio ambiente en las mejores condiciones e incluso proceder a su reutilización, las estaciones depuradoras de aguas residuales (EDARs) las someten a un tratamiento en virtud del cual adquieren las características de calidad previstas en la legislación vigente. En el Municipio de Alicante, se dispone de dos estaciones depuradoras de agua residual.

| Agua reutilizada | 12.000.000 m3/año |

|---|---|

| Energía cogenerada | 2.500.000 KW/año |

| Lodos agricultura | 5.600 Toneladas / año |

| Lodos secado térmico | 22.000 Toneladas / año |

| Residuos eliminados | 1.400 Toneladas / año |

Las instalaciones encargadas de depurar las aguas residuales en Alicante son las EDARs de Rincón de León y Monte Orgegia.

La Estación Depuradora de Aguas Residuales de Rincón de León da servicio a la mayor parte del casco urbano de Alicante y a la localidad de San Vicente del Raspeig. Tiene una capacidad de tratamiento de 75.000 m3/día.

La otra Estación Depuradora de Aguas Residuales de Monte Orgegia da servicio a la zona norte del término municipal de Alicante, zona de playas, Villafranqueza y parte de los municipios de El Campello, San Juan de Alicante y Mutxamel. Tiene una capacidad 60.000 m3/día.

Ambas depuradoras son plantas de tratamiento convencional por fangos activos y digestión anaerobia con dos líneas de tratamiento de agua.

Datos relevantes del año 2018 para ambas EDARs:

| Habitantes equivalentes servidos | 545.000 habitantes |

|---|---|

| Total Agua Depurada | 28.000.000 m3 |

-

Cogeneración (Rincón de León)

Como consecuencia de la fermentación de los lodos se genera biogás, el cual está compuesto principalmente por metano, y éste es reciclado y transformado gracias a un motogenerador en energía, que es utilizada para el funcionamiento de una parte de la depuradora. En la EDAR de Rincón de León se cogeneran 2.500.000 kWh anualmente, aproximadamente el 25% de las necesidades energéticas de la planta.

-

Energía fotovoltaica (Rincón de León)

Se generan 37.000 kWh anualmente a través de las placas solares instaladas en la planta. Se trata de una pequeña parte de la energía consumida total en la EDAR.

-

Residuos generados en el proceso de depuración

Los residuos generados en el primer proceso de la depuración son: residuos sólidos urbanos de diferente granulometría, arenas y grasas. Todos ellos son tratados según la legislación vigente de residuos por gestores autorizados, y son transportados a las plantas de tratamiento de residuos correspondientes.

Además, se generan otros residuos (envases, plásticos, etc.) en el proceso y operaciones de mantenimiento que son tratados según la legislación vigente de residuos mediante gestores autorizados.

-

Valorización de fangos

Antes de proceder a la evacuación de los fangos, éstos se deben tratar adecuadamente para reducir su poder de fermentación y adaptarlos convenientemente para su reutilización, a la par que reducir su volumen para el trasporte.

En el proceso de digestión anaerobia, la materia orgánica es convertida en metano y dióxido de carbono en dos etapas. El fango que sale de digestores se lleva a un proceso de deshidratación para eliminar la mayor cantidad de agua posible.

Una vez deshidratado, el aspecto del fango y sus propiedades se asemejan al abono orgánico, utilizándose actualmente como tal una parte de la producción del mismo.

El biogás obtenido dispone de un contenido de metano del orden de 65% aproximadamente, pudiendo aprovecharse para la producción de energía eléctrica.

Los lodos procedentes de depuración se aprovechan, siendo sus principales destinos la valorización térmica y la aplicación agrícola como abono orgánico.

A continuación se describen los volúmenes de fango aplicados según su uso:

- Total Lodos para valorización térmica: 22.000.000 Kg.

- Total Lodos para aplicación en agricultura (kg): 5.600.000 Kg.

Mención especial merece la valorización térmica de los lodos extraídos en el proceso de depuración de las aguas residuales, realizada en el secado térmico de fangos.

La planta de secado térmico de lodos se localiza dentro del recinto de la fábrica de cemento de Cemex en Alicante. Existen dos líneas de tratamiento en paralelo mediante un sistema de secado que se basa en hacer circular aire caliente dentro del lodo, de manera que se evapore el agua contenida, la cual es condensada posteriormente.

Funcionamiento de los Túneles:

El volumen de lodos secos obtenidos se dirige al horno de producción de cemento donde su utiliza como combustible, convirtiéndose así en una alternativa sostenible al uso de combustibles fósiles como el carbón. El calor residual de este horno sirve para calentar el agua utilizada para el secado del lodo. De aquí la gran importancia ambiental de este sistema de tratamiento en esta instalación pionera en España: es sostenible energéticamente al no requerir el aporte de fuentes de energía no renovables (fuel-oil, gas natural, carbón…) y producirse la valorización térmica del residuo.

Así, se cierra el ciclo de depuración mediante la autogestión y posterior valorización del principal residuo del proceso del tratamiento de las aguas residuales.